Product

Efficientby Design

The Same, But Better

With global economies desperately in search of replacements to traditional polymers and chemical intermediates produced from non-renewable feedstocks, Novomer’s proprietary catalyst system provides access to lactone monomers in high yield and high selectivity from readily available, cheap, sustainable feedstocks through the Novo22™ loop.

Lactone monomers are highly valuable intermediates in the synthesis of a family of biodegradable polymers and can easily be transformed to other industrially important polymer intermediates such as Acrylic Acid, Succinic Anhydride, Acrylamide and Acrylonitrile. These polymers can be of higher purity than intermediates from competing technologies, with minimal waste produced, that can be seamlessly dropped into current product production steams. The properties and composition of Novomer’s core polymer product, Rinnovo, can be tailored to meet the desired needs of the customer.

Current Portfolio Products

Novomer has developed a cost-competitive, sustainable route to produce glacial acrylic acid (GAA) from plant-based and renewable feedstocks. The monomer is created via thermolysis of poly(3-hydroxypropionate), or p(3HP). p(3HP) is synthesized via polymerization of beta-propiolactone, which is produced using the CoEth process that reacts ethylene oxide (EO) and carbon monoxide (CO). p(3HP) is hydrophobic, stable under ambient conditions, transportable in a variety of standard containers, storable for extended periods of time, and requires no special handling. A key benefit of this route is that p(3HP) may be readily converted to GAA “on demand” at a customer site. This conversion process is quantitative and produces GAA with greater than 99.9% purity. This approach allows GAA, in the form of p(3HP), to be shipped around the world under ambient conditions without need of stabilizers or refrigeration. It can then be inventoried and used as needed. GAA consumers no longer need to be located adjacent to an acrylic production facility.

How It Is Used

Acrylic acid is used in the production of paints, coatings, adhesives, sealants, plastics, detergents, flocculants, and absorbent and super absorbent polymers.

Features

GAA made from p(3HP), when used in the production of certain super absorbent polymers, has shown improvements in retention capacity and absorbency speed compared to conventionally produced GAA. This performance improvement has been attributed to the exceptional purity of GAA derived from the p(3HP) product.

Rinnovo polymers are Novomer’s proprietary class of compostable polymers synthesized from lactone monomers. Novomer’s first target, Rinnovo™ 3HP H1000 XP is a high molecular weight poly(3-hydroxypropionate), a homopolymer of beta-propiolactone. The homopolymer has attractive mechanical and physical properties that make it suitable for packaging and other thermoplastic applications. It is an aliphatic polyester that is stable and easily transportable.

How It Is Used

Rinnovo™ 3HP H1000 XP can be used as an alternative to conventional, petroleum based polymers, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Potential applications include packaging films, agricultural films and waste collection. Further, it has excellent oxygen barrier properties, biodegradability, and reduced environmental impact.

Features

Rinnovo™ 3HP H1000 XP has a structure similar to those of two other aliphatic polyesters, polyhydroxybutyrate (PHB) and polycaprolactone (PCL), and can be degraded in the same, diverse, set of environments. The polymer is classified as biodegradable under the standards of EN 13432 and ASTM 6400. Importantly, the polymer has also been demonstrated to be recycled and processed to form acrylic acid using a lower energy intensity thermolysis process.

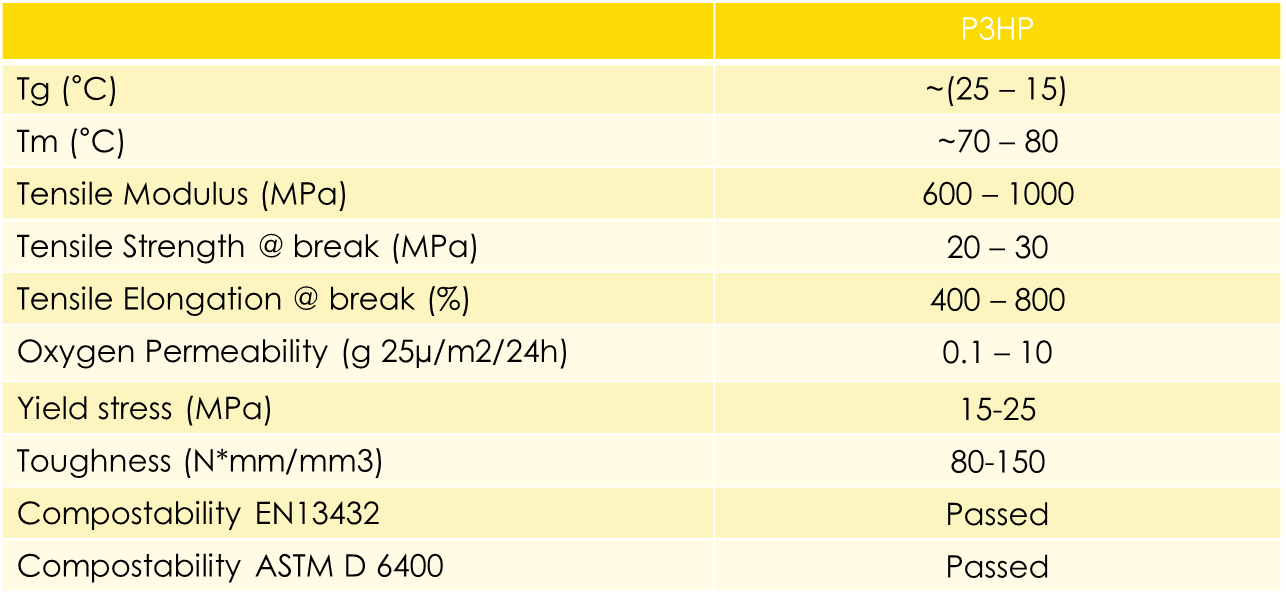

Typical Properties of Rinnovo™ 3HP H1000 XP

Funded Development Opportunities

As a platform monomer technology, there are several derivatization opportunities to take advantage of the lactone intermediate. While Novomer is currently not focusing on these product classes, Novomer would consider funded development with interested partners.

- Acrylamide

- Functionalized Lactones

Novomer Innovation Center

The Novomer Innovation Center is designed to meet the expanding demands of our growing sustainable chemical business. The new 26,000 square foot facility houses technology research, product development activities and a Demonstration Unit to make customer samples for a variety of products. Novomer is expected to employ about 60 chemists, engineers, lab technicians and other personnel at the new facility.