Impact

Empowered bySustainability

Creating the Future Today

Our impact strategy begins with its thoughtful design in catalysis and engineering. We understand that our catalyst and process technology is fundamental to a message of a low impact. The catalyst we employ has high selectivity, can be operated in liquid phase, and can be run at low temperatures (<100°C). These features enable low process waste and low energy consumption. Accordingly, the greenhouse gas contributions from our conversion technology are highly favorable relative to most industrially produced polymers.

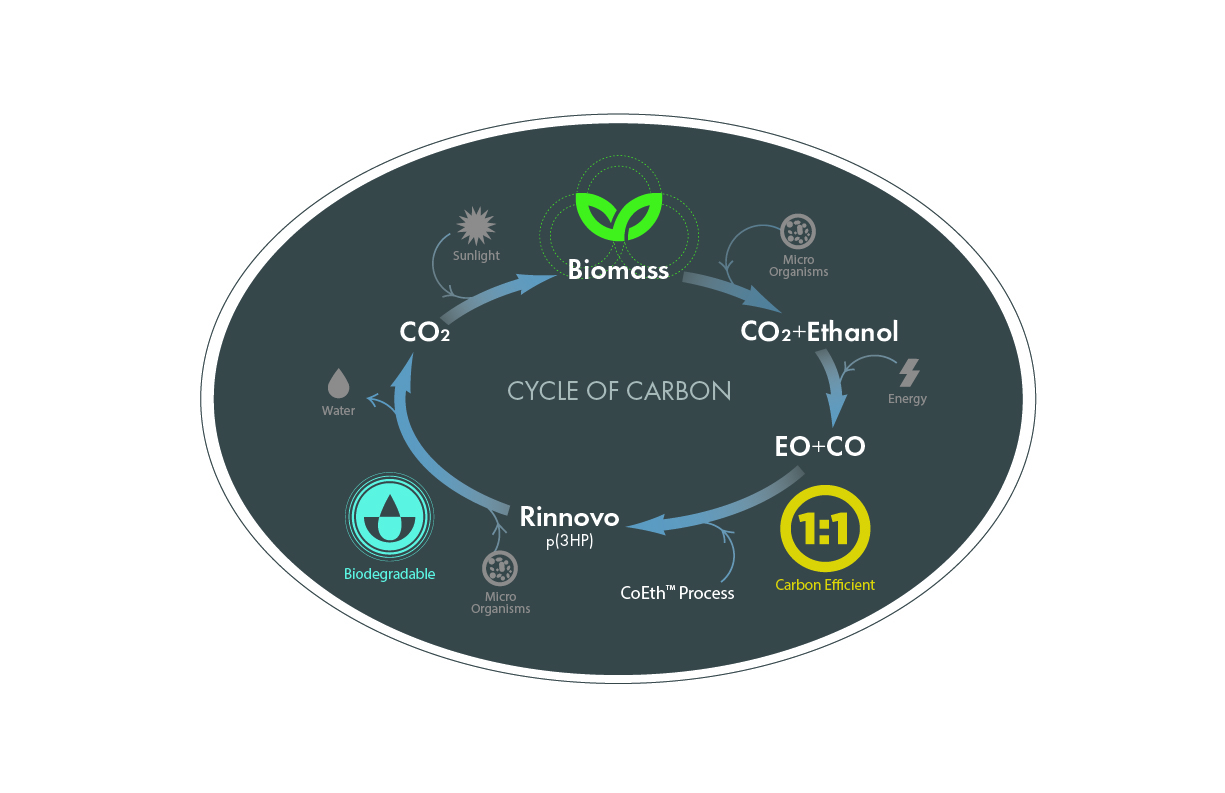

Novomer's Circular Economy

While impact starts with our catalyst and process engineering, our technology enables opportunities both in feedstock sourcing and in end of life polymer disposal. As a C1/C2 feedstock technology, we are able to cost effectively source both C1 and C2s from renewable sources. C1s are produced from biomass and other waste streams while C2s are sourced from sugar. By utilizing these feed streams we are able to deliver a fully sustainable source of feedstock to our customers. We are also able to provide a breadth of end of use options for our polymers. Our core product, Rinnovo, can be composted, recycle or upcycled to Acrylic Acid via thermolysis. By offering customers a choice, they can choose the most economic means of disposal without relying on landfills, incineration or pollution of waterways.

1:1 Carbon Utility

At Novomer, we value every carbon in the value chain. Starting with our feedstock, our goal is that every carbon sourced is converted into usable end product. This is how we define 1:1. Further, via recycling or upcycling of our Rinnovo polymers, our customers can achieve 1:1 carbon conversion to Acrylic Acid via thermolysis. Alternatively, through composting, our products are efficiently degraded without causing harm to our environment.

Conversion Efficiency

Our process is highly carbon efficient. An important feature of the base catalyst is selectivity to our target products. We have proven target product selectivities of >95%, which leads to low waste, high recovery and low capital costs.

Cycle of Carbon

While many circular economy diagrams involve many “gears”, our impact concept is simple: start with sustainable feedstock, convert it as efficiently as possible and return it back to its original form to start the process over. Our CoEth process, when combined with biomass sourcing and composting in ambient environments, results in preferred environmental outcomes.